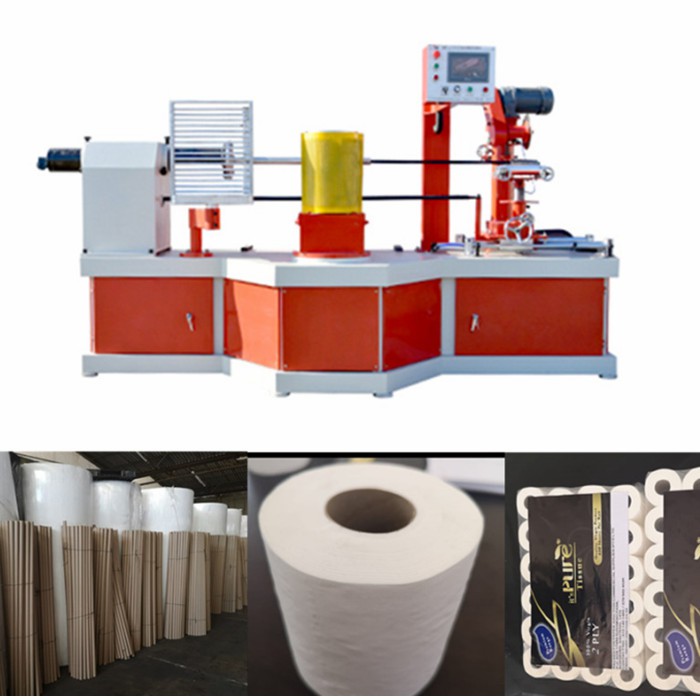

Paper Core Cutting Machine

Product Introduction:

It is is an energy-efficient equipment of an experimental manufacture,which has been taken a lot advantages by our factory's technical personnel in the operation of making toilet paper cores,combined with practical experience.

Technical Specification:

Model | MJC-1 |

Core Diameter | 35-60mm |

Speed | 0-15m/Min |

Main Motor | 2.2kw |

Auxiliary motor | 0.37kw |

Dimension: | 3000*1800*1400mm |

Weight | 1000kg |

Features:

1.The Paper Core Cutting Machine is compact structure,less occupied area, low power, high efficiency, without a fixed installation, put stability is enough to be used.

2.Easy operation, low noise, two persons are enough to operate the whole machine.

3.The tube rollers diameter is adjustable , just need replace the spindle core thickness.

4.This Paper Core Cutting Machine is suitable for a variety of coil papers to make tubes (such as craft paper, toilet paper, liner paper, etc.)

5.Automatic paper glueing,speed is controllable,the length can be arbitrary cutting,easy to operate.

Working Principle:

It is with speed motor, through the drive, driven paper tape belt, the first plate opened the feed reel and reel axis interchange. Then the second plate of paper is pulled through the sizing tank to be automatically sizing and fed into the intersection of the paper roll and the winding shaft. The paper is continuously wound to form a paper core from roll paper and cut according to required specifications.

Matters Needing Attention:

1)It has been commissioned before leaving the factory, please check if there is a loose screw before starting, and if the line is intact.

2)Empty machine running a few minutes to see if the rotation direction of operation is correct, no noise, smooth operation, then shut down. Open the paper plate and feed it to the intersection of the drive belt and the paper roll axis. Then slowly turn the speed dial knob to start work, leaving the hand same time,to avoid putting the hand in danger.

3)Feeding the first paper roll when a plate of paper opened to feed, and then opened another plate of paper, gluing through the sizing slot and then feed.

4)Boot speed must be slow, and then gradually speed up, adjust just around the corner.

5)Before starting the glue into the sizing tank, when stop working ,put the glue poured out, remove the sizing wheel, soaked into water and wash clear , for using in the next time.

Hot Tags: paper core cutting machine, China paper core cutting machine suppliers, manufacturers, factory, fully automatic paper cup machine, fully automatic paper cup making machine, high speed paper cup forming machine, paper cup machine for sale, small paper cup making machine, paper cup making machine price